Communication cabinet installation for overseas projects

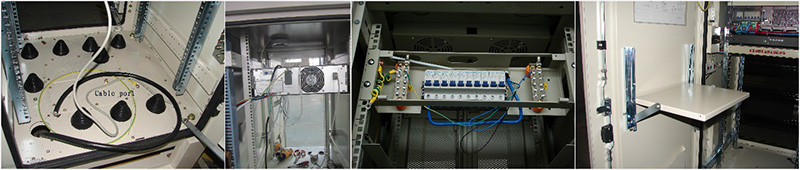

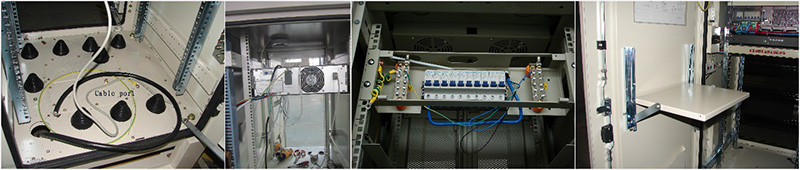

Outdoor communication cabinet refers to a cabinet/enclosure that is directly working in the natural environment, made of metal or non-metal materials, providing outdoor physical working environment and safety system for wireless communication stations or wired network station. It is suitable for outdoor environment, such as roadside, park, roof, mountain etc . With base station equipment, power equipment, battery, temperature control equipment, transmission equipment and other ancillary equipment installed inside. With suitable space and heat exchange capacity, providing reliable mechanical and environmental protection for the normal operation of internal equipment.

Outdoor cabinet application:

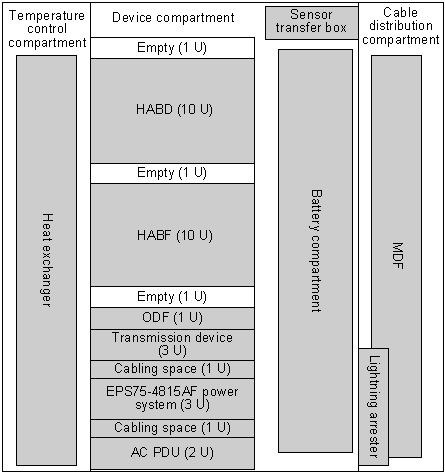

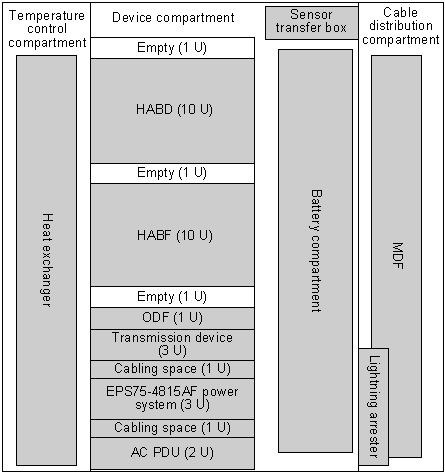

â– Used for DSLAM , 4G network, FTTX network EPON, GPON access

â– The equipment compartment of the outdoor cabinet is designed according to the standard cabinet size.

â– Configurable installation of DLC, SDH, DSLAM, network switch and multimedia gateway

â– Network transformation or organization, smooth transition to next-generation NGN network

â– The heat exchange compartment is installed with heat exchangers or air conditioning equipment according to customer requirements.

â– Low cost, easy site selection, easy construction; increase access rate

Temperature management solution:

External heat source: radiant heat, conduction heat

Internal heat source: battery, power supply, main equipment

Heat is concentrated in the upper part of the cabinet, which is the key for cooling.

Solution: external thermal insulation coating, internal heat dissipation PU sandwich components

Solution: Natural ventilation, fan / heat-exchanger / air-conditioner / TEC cooling.

Cabinet safety solution:

1>The cabinet components are designed with “PU sandwich†structure to minimize external heat conduction, so that the internal temperature does not change sharply with external temperature to prevent condensation.

2>The cabinet covered with magnesium-aluminum-zinc steel plate. The surface coating contains 85.8% zinc, about 11% aluminum, about 3% magnesium, and about 0.2% silicon. The addition of silicon not only improves the processing performance of zinc-containing aluminum plated steel. Its combined action with magnesium further enhances the corrosion inhibition effect.

3>Automotive seal design, hollow structure. Shielded steel belt reinforced and has certain EMC function. EPDM rubber body material, resistant aging life of 15 years. Easy to replace and maintain

4>The lock body is made of reinforced zinc-aluminum alloy and high mechanical strength.

Keyhole double seal with key can be customized according to user requirements

5>Monitoring system

Remote control system for door sensor, smoke sensor, water sensor, temperature sensor, humidity sensor, shake sensor etc. RS485/232 communication.

6>Earthing and lightening protection (option for customers)

Class A 60KA multi-lightning and energy-rich area

Class B 20KA-40KA multi-lightning area

C-class 20KA general lightning area

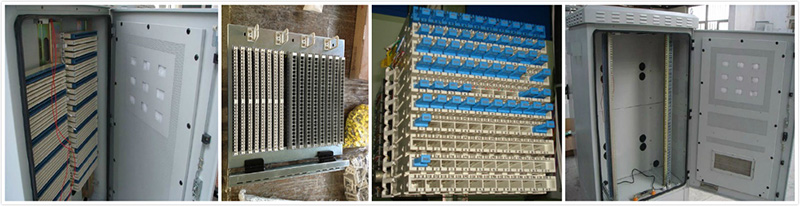

MDF/ODF wiring solution:

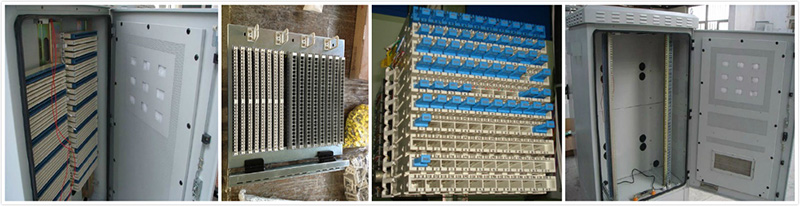

Projects for overseas:

Outdoor cabinet application:

â– Used for DSLAM , 4G network, FTTX network EPON, GPON access

â– The equipment compartment of the outdoor cabinet is designed according to the standard cabinet size.

â– Configurable installation of DLC, SDH, DSLAM, network switch and multimedia gateway

â– Network transformation or organization, smooth transition to next-generation NGN network

â– The heat exchange compartment is installed with heat exchangers or air conditioning equipment according to customer requirements.

â– Low cost, easy site selection, easy construction; increase access rate

Temperature management solution:

External heat source: radiant heat, conduction heat

Internal heat source: battery, power supply, main equipment

Heat is concentrated in the upper part of the cabinet, which is the key for cooling.

Solution: external thermal insulation coating, internal heat dissipation PU sandwich components

Solution: Natural ventilation, fan / heat-exchanger / air-conditioner / TEC cooling.

|

Temp mode |

Control |

IP |

Request |

Cost |

Maintenance |

|

Fan |

Good |

55 |

+5℃ to +7 ℃ |

Lowest |

OK |

|

Heat-ex |

Better |

65 |

+12℃ to +15 ℃ |

High |

OK |

|

Air-con |

Best |

66 |

Low |

Higher |

OK |

Cabinet safety solution:

1>The cabinet components are designed with “PU sandwich†structure to minimize external heat conduction, so that the internal temperature does not change sharply with external temperature to prevent condensation.

2>The cabinet covered with magnesium-aluminum-zinc steel plate. The surface coating contains 85.8% zinc, about 11% aluminum, about 3% magnesium, and about 0.2% silicon. The addition of silicon not only improves the processing performance of zinc-containing aluminum plated steel. Its combined action with magnesium further enhances the corrosion inhibition effect.

3>Automotive seal design, hollow structure. Shielded steel belt reinforced and has certain EMC function. EPDM rubber body material, resistant aging life of 15 years. Easy to replace and maintain

4>The lock body is made of reinforced zinc-aluminum alloy and high mechanical strength.

Keyhole double seal with key can be customized according to user requirements

5>Monitoring system

Remote control system for door sensor, smoke sensor, water sensor, temperature sensor, humidity sensor, shake sensor etc. RS485/232 communication.

6>Earthing and lightening protection (option for customers)

Class A 60KA multi-lightning and energy-rich area

Class B 20KA-40KA multi-lightning area

C-class 20KA general lightning area

MDF/ODF wiring solution:

Projects for overseas: