With the continuous development of the social economy, the value of electricity supply is becoming more and more important to all social industries. Various cables, especially high-voltage power cables which may have excessive load or aging of cable joints then caused temperature raised. Once the temperature too high will cause a fire and result in interruption of the transmission business. Therefore, an on-line temperature measurement detection technology is urgently needed to automatically collect the surface temperature of the cable in real time and accurately monitor the temperature change then issue an early warning before the temperature is too high, so that the owner has sufficient time to take corresponding measures to avoid the fire.

Warner Telecom has developed a power cable temperature measurement detection system to monitor the temperature of the cable in real time and provide early warning and alarm. The system adopts the all-fiber sensing passive temperature detection method, which eliminates the safety hazard and greatly improves the usability of the monitoring system for power temperature monitor.

This system mainly composed of temperature detection cable, temperature detection host, industrial computer controller, PC monitoring software, etc.

Our fiber cable temperature measurement/detection monitor has 2/4/8 channels with testing coverage can be expanded. The cable coverage distance up to 2KM, 4KM, 8KM, 10KM. According to the project requirements, we choose 2 channel/4km temperature measurement/detection host and 4 channels/2km temperature measurement/detection host. The output signal from the temperature measuring host will send to the host computer for centralized display and alarm output, also could be send to the fire alarm controller for alarm and fire linkage. For centrally monitor all temperature detection hosts at the remote terminal, we will add remote communication module for each temperature detection host for a better centralized monitoring remotely.

Fiber cable temperature detection/monitoring system items list:

|

No. |

Items |

Spec |

QTY |

Remark |

|

1 |

Host computer |

Screen & Mouse |

1PCS |

Option |

|

2 |

Temp monitoring -1 |

2 channel/4km |

1PCS |

|

|

3 |

Temp monitoring -2 |

4 channel/2km |

6PCS |

|

|

4 |

Temp sensing cable |

62.5/125um SM |

30000M |

|

|

5 |

Fiber splice closure |

|

7PCS |

|

|

6 |

Fiber cable |

E2000/APC |

15PCS |

|

|

7 |

Phone alarm module |

|

1PCS |

Option |

|

8 |

Cabinet |

2000*800*800 |

3PCS |

Option |

|

9 |

Linkage alarm module |

16 port |

4PCS |

Option |

|

10 |

Exchanger |

8 port |

1PCS |

|

|

11 |

FOT |

1 optical port 2 power port |

2PCS |

|

|

12 |

FOT |

2 optical port 2 power port |

1PCS |

|

|

13 |

Feeding fiber |

|

Sufficient |

|

1. Fiber optic cabling requirements

1) The temperature-sensitive fiber stored in the cable tray. The protective package is retained prior to installation.

2) The bending radius of the temperature-sensitive fiber must be greater than 30mm. Do not wear or crush the temperature-sensitive fiber when passing through the wall or through the pipe.

3) The temperature-sensitive fiber is forbidden to be scrambled, strongly twisted or stretched excessively to avoid damage of the fiber core.

4) After the fiber unpacking, check whether the appearance of the fiber is damaged or not.

5) The laying of the optical fiber should be naturally straight.

6) Both ends of the fiber should be labeled with the written number clearly and correctly.

7) Connect and protect the fiber with the fiber splice closure should meet the installation process requirements.

8) During the fiber wiring process, 5 meters fiber should be left every 200 meters for future cable damage connecting.

9) 20 meters of fiber should be left at the beginning and end of the tunnel respectively for testing.

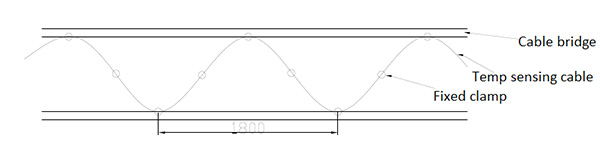

2. Temperature measurement detection fiber laying

When the temperature-sensing cable installed on the cable tray, it should be sinusoidally laid on the outer sheath of the protected power cables, better to use contact installation. Please find following:

3. Installation of the temperature measurement/detection host

The standard 19-inch network cabinet (OEM design) with temperature measurement detection host install inside occupying 3U height, AC 220V or DC 24V power supply. For other components (such as the local computer, fire power supply, etc.), please refer to the relevant product instructions for installation in the cabinet.

4. After-sales service and market application

This is a fully automatic unattended system, which does not require any personnel to be on duty during operation and does not incur any operating costs. We assure 3 years warranty after the project acceptance. After the expiration of the warranty, we also carry out long-term maintenance services, and collect the accessory cost and maintenance time.

Our temperature measurement detection system has been used in many projects domestically and achieved great success, we also exported to Southeast Asia with good market.